How To Set Up Frame Scaffolding

Oct 20, 2023

Frame scaffolding is one of the most commonly used types of scaffolding in construction, known for its stability, ease of setup, and versatility. Properly setting up frame scaffolding ensures a secure platform for workers and equipment, reducing the risk of accidents. This guide provides a step-by-step overview of the setup process and important safety considerations for frame scaffolding installation.

Tools And Materials You'll Need:

Frame scaffold components (vertical frames, horizontal braces, cross braces, and platforms)

** Base plates or screw jacks

** Leveling tools (spirit levels)

** Planks or scaffold boards

** Coupling pins and clips

** Safety equipment (hard hats, safety harnesses, fall protection)

** Hammer and wrenches

** Toe boards and guardrails (for safety)

** Scaffold tags and warning signs (for compliance)

Step-By-Step Guide To Setting Up Frame Scaffolding

Step 1: Assess the Work Area

Prior to commencing scaffold assembly, evaluate the work area to confirm its suitability for scaffold positioning. Check for any obstacles, uneven ground, or overhead obstructions. Clear the area of debris or obstacles that could interfere with the scaffold's stability.

Step 2: Prepare the Foundation

In case of uneven ground, utilize base plates or screw jacks to establish a stable and level scaffold foundation. Adjust the screw jacks or base plates until the scaffold is level both horizontally and vertically. Use leveling tools such as spirit levels to ensure accuracy.

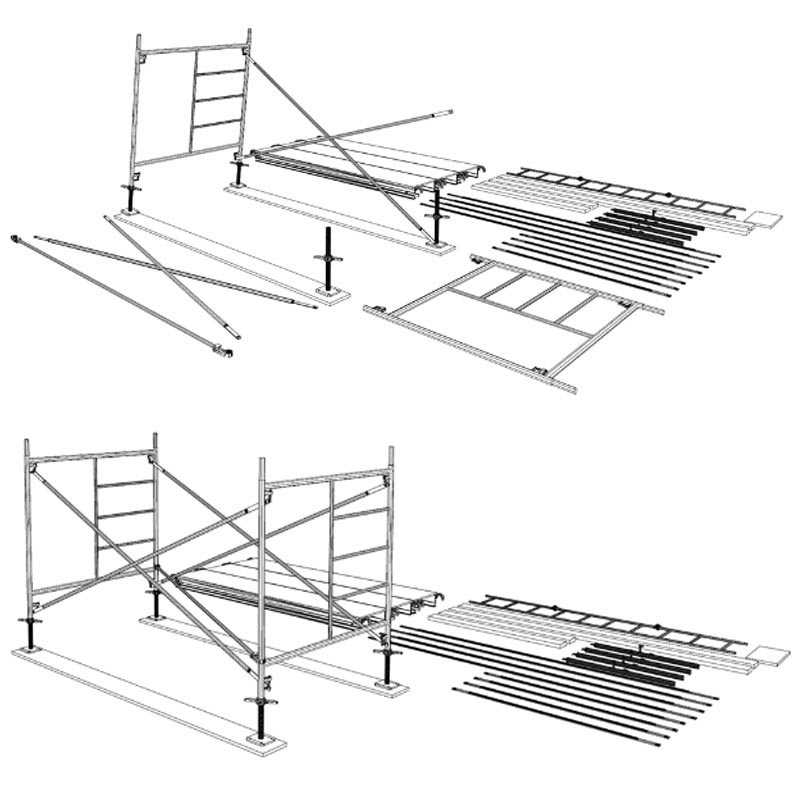

Step 3: Assemble the Vertical Frames

Begin by assembling the vertical frames (also called uprights or standards). Place the frames on the base plates or screw jacks at the desired locations. Make sure the frames are plumb (perfectly vertical) and secure them in place.

Step 4: Install Cross Braces

Install cross braces between the vertical frames. Cross braces provide lateral stability to the scaffold. Typically, they should be installed diagonally from the bottom of one frame to the top of the adjacent frame. Secure them in place using coupling pins and clips.

Step 5: Add Horizontal Braces

Install horizontal braces between the vertical frames at the desired heights. These braces provide additional support and prevent the frames from spreading apart. Secure them using coupling pins and clips.

Step 6: Place Platforms

Place the scaffold platforms (also called walk boards) on the horizontal braces. Ensure they are secure and supported evenly. The platforms should overhang the frames slightly but not excessively. They should also have adequate space for workers and materials.

Step 7: Secure Guardrails and Toe Boards

For safety, install guardrails and toe boards on the platforms to prevent falls. Ensure that guardrails are properly secured and meet safety standards.

Step 8: Perform Safety Checks

Before allowing workers to access the scaffold, conduct safety checks. Inspect all components for damage or defects. Ensure that all couplings and connections are secure. Confirm that the scaffold is level and stable.

Step 9: Tag and Sign the Scaffold

Place scaffold tags and warning signs at accessible locations to indicate that the scaffold has been inspected, is safe for use, and its weight capacity.

Step 10: Train Workers

Ensure that workers using the scaffold are trained in scaffold safety, including the safe use of fall protection equipment.

Step 11: Regular Inspections

Throughout the project, regularly inspect the scaffold for any signs of wear, damage, or instability. Make necessary adjustments and repairs promptly.

By following these steps and adhering to safety guidelines and regulations, you can set up a frame scaffold safely and efficiently for your construction or maintenance project. Keep in mind that prioritizing safety is crucial when working with scaffolds.

Key Safety Tips For Frame Scaffolding Setup

Manufacturer Guidelines: The manufacturer must be followed regarding construction and maximum load capacity.

Personal Protective Equipments: No assembly should be carried out without proper protective gear-a hard hat, gloves, and boots.

Don’t Exceed the Load Limits: Scaffolding is not to be overloaded. Each platform has a specific weight capacity-a measure for both workers and materials.

Don’t Overreach: Reaching outside the platform edges will tip an erection scaffold.

Regular Inspection: Daily inspections of scaffolding should always be done. They should ascertain if it is safe enough to work on following the exigencies of turbulent weather-following rain storms and snowstorms-for-the integrity of the structure.

FAQ

What Are The 2 Main Types Of Framed Scaffold?

There are two main types: door frame scaffolding and ladder frame scaffolding

Which Type Of Scaffold Is Prohibited?

The use of shore or lean-to scaffolds is prohibited.

What Is The Maximum Gap On Scaffolding?

Standards require that the spacing between scaffolding boards or between scaffolding boards and uprights should not exceed one inch.

Read More

Supported Scaffolds -Frame or Fabricated -- OSHA

What Is A Frame Scaffold -- QUORA

What Is Scaffolding -- FLYABILITY