Plywood Sheet Size: What You Need To Know

Nov 13, 2024

Plywood Size Introduction

Plywood is perhaps among the most widely used building materials. It is applied in construction, assembly work, furniture, cabinets, and even decorative projects. That is why it is important to know the dimensions of plywood so as to select the very right kind for each project, which in turn helps reduce waste and thus assure a good fit and structural integrity.

Standard plywood sizes are not uniform around the world. America, India, the United Kingdom, and the Philippines all have their own traditionally favored sizes, which quite often influences their availability-a range for compatibility in the local markets.

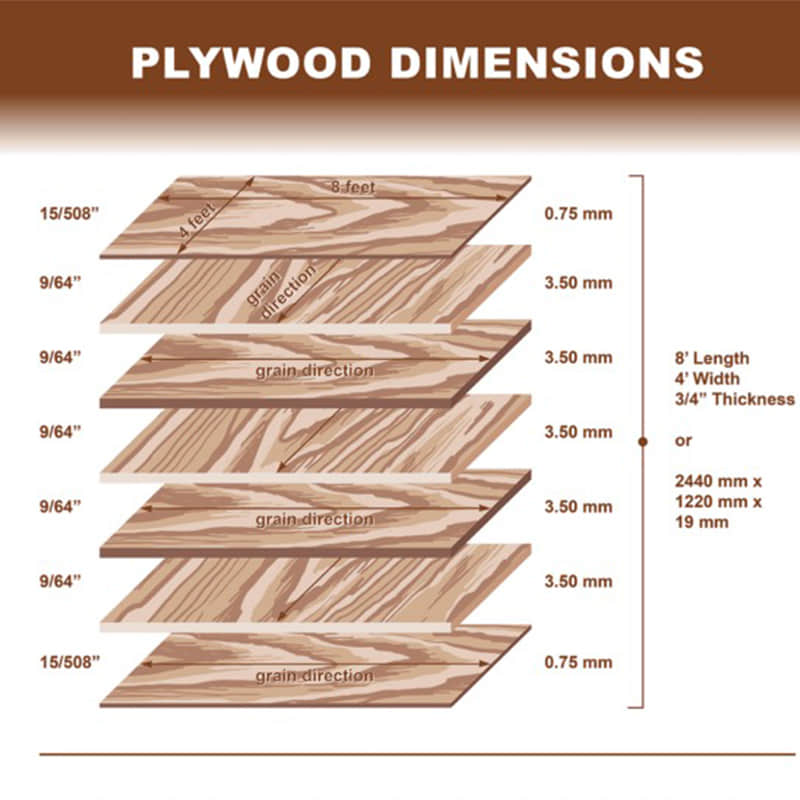

What Is The Standard Size Of A Sheet Of Plywood

Plywood is available in several different standard sizes and special thicknesses, depending on its applications in construction, furniture, and other fields. While some sizes are standard across industries, size is also determined by regional and purpose-specific factors.

Common Industry Sizes: The most widely used sizes include the standard 4 ft x 8 ft (1.22 m x 2.44 m), due to being apt for various construction jobs because of compatibility with common framing systems. Another very common size is 5 ft x 5 ft (1.52 m x 1.52 m). This is especially prevalent in Europe, being widely used for specific applications to furnishing and cabinetry.

Standard Thickness Options: Plywood is sold in various deviated thicknesses, commonly expressed in inches or millimeters. Common plywood standard thickness mm include:

1/4 inch (6 mm): This thickness is suitable for small projects or projects that require only simple folding-such as lining or sliding drawers.

1/2 inch (12 mm): Often used to make furniture or cabinets. This is a typical thickness for a typical half-inch plywood subfloor, but not suitable for all subflooring application examples.

3/4-inch (18 mm): This is the most common plywood thickness, suitable for almost all plywood construction. This is also a suitable floor or ceiling thickness.

Regional Differences In Plywood Sheet Size

Plywood dimensions vary by region, as different countries have their own standards and preferences. Understanding these regional dimensions is critical, especially for projects that involve sourcing materials internationally or adhering to local building codes.

Indian Common Plywood Sizes

According to "Indian Standard, IS:10701:2012" (Structural Plywood - Specification) and "IS:303:1989" (General Plywood Specification) , the common sizes are:

· 2.4 x 1.2 m (8 x 4 ft)

· 2.4 x 0.9 m (8 x 3 ft)

· 2.1 x 1.2 m (7 x 4 ft)

· 2.1 x 0.900 m (7 x 3 ft)

· 1.8 x 1.2 m (6 x 4 ft)

· 1.8 x 0.9 m (6 x 3 ft)

Common thickness: 3mm, 4mm, 6mm, 9mm, 12mm, 15mm, 18mm, 25mm

UK Plywood Dimensions

According to the british standards BS EN 315, common sizes of plywood are as follows:

· 2.44 x 1.22 m ( 8 x 4 ft )

· 2.74 x 122 m ( 9 x 4 ft )

· 3.05 x 1.22 m ( 10 x 4 ft )

· 2.40 x 1.22 m ( 7.8 x 4 ft )

· 2.50 x 1.22 m ( 8.2 x 4 ft )

Common thickness: 3mm, 6mm, 9mm, 12mm, 15mm, 18mm, 21mm, 24mm, 25mm

Plywood Sizes In The Philippines

According to the standards of the Philippine Board of Standards (BPS) , the common sizes of plywood are as follows:

· 8x4 ft (2440mm x 1220mm)

· 7x4 ft (2135mm x 1220mm)

· 6x4 ft (1830mm x 1220mm)

· 6x3 ft (1830mm x 915mm)

Common thickness: 3mm, 4mm, 6mm, 9mm, 12mm, 15mm, 18mm, 25mm

Dimensional Tolerance

The dimensional tolerance of plywood indicates the permissible ranges of deviations during the manufacture of plywood. Tolerance arises in the course of manufacturing since the wood being used is a natural material that can undergo changes in response to environmental vitiants like humidity and temperatureore. An outline of some more commonly spoken about aspects of the plywood dimensional tolerance includes:

Length And Width Tolerance:

For standard size plywood (such as 8x4 feet), the tolerance for length and width is generally between ±3 mm and ±5 mm. This means that plywood with a nominal size of 2440 mm X 1220 mm may actually be between 2435 mm and 2445 mm, with a width between 1215 mm and 1225 mm.

Thickness Tolerance:

Usually, the range of this tolerance is small, around ±0.5mm to ±1mm. Between 17.5mm and 19mm, for instance, is under consideration when dealing with a nominal plywood measurement of 18mm.

Flatness And Straightness:

Flatness and straightness tolerances are assigned to plywood to permit it while still shed light upon the status, therein to make certain that the sheet stays flat and the edges remain straight. These tolerances have, in general, been expressed as deviation per meter in measurements.

National Standards:

The National Standards vary beyond borders and applicable jurisdictions. For example:

ISO 10983: Plywood standard developed under the authority of the International Organization for Standardization (ISO).

BS EN 315: British Standard (BS) dimensional tolerances for plywood.

ASTM D1037: American Society for Testing and Materials (ASTM) standard for testing plywood, including dimensional tolerances.

PNS: Philippine National Standards (PNS) articulate the dimensional tolerances of plywood.

Manufacturer's Standards:

The idea of manufacturer own standards is simple: some manufacturers have their own internal standards; some may exceed national or international standards in an attempt to ensure greater quality.

Tolerances exist to capture the deviations that occur during the manufacturing process; however short, the product must remain effective and usable in the actual clearance. When it comes to buying plywood, understanding the tolerances involved can aid you in planning and executing your projects better.

Plywood Sizes And Prices

Plywood size is directly proportional to price: Size of plywood positively correlates with price. For instance, a standard 4 by 8 ft sheet of plywood may cost $15-$30, whereas an oversized sheet, either 4 by 7 ft or even smaller sized 6 by 4 ft, may generally range from $20 to $40. Thickness of wood also influences pricing,18 mm-thick sheets are way costlier than their 12 mm-thick cousins and are typically pegged from ten to twenty percent extra. The demand, quality of materials, cost of production, as well as other factors also influence price, although size remains variously cited as one of the more prominent determining factors.

How Plywood is Made

In plywood manufacture, high-quality wood is selected for the core material, followed by sawing into thin wood slices or veneers. Nursing by rotary-cutting or slicing produces veneer of varying thicknesses. Following, these veneers dry off to reduce moisture content, and adhesives bond these veneers together layer by layer. The grain direction of each layer of veneer is alternated with subsequent layers: usually perpendicular to the adjacent layers of veneer during lamination to enhance strength and stability. Afterwards, glued plywood is cured and pressed directly or with the help of hot or cold methods. Ultimately, these plywood panels are trimmed to standard size and gone under various surface treatments like sanding or painting to enhance their look and durability. The entire process requires precise control of temperature, humidity and pressure so as to guarantee the quality and service performance of the plywood.

Types Of Plywood Core

There are many types of core materials for plywood. Here are some common types of plywood core materials:

Lumber core: A solid wood core (of solid wood strips or blocks) is generally softwood (like pine) or hardwood-such as eucalyptus. These plywoods, with their solid wood cores, tend to have good structural strength and are used for the bearing of loads.

Veneer core: Thin sheets (veneers) of wood are stacked and glued at right angles to the adjacent layers to improve strength and stability. Lightweight and good at resisting bending.

MDF core: The core material of MDF core plywood is made from pressed wood fibers with a resin adhesive that has a smooth surface and has good processing properties.

Particle board core: The core is made from pressed wood chips with resin binder, which gives the core improved stability and reduced likelihood of warping, better than other materials.

How Heavy Is A Sheet Of Plywood

Here are some approximate weights for a standard 4x8 foot sheet:

1/4 inch (6mm): Around 22-24 pounds (10-11 kg)

1/2 inch (12mm): About 40-45 pounds (18-20 kg)

3/4 inch (19mm): Approximately 60-65 pounds (27-29 kg)

Keep in mind:

Wood Species: Different species of wood have different densities. For example, birch plywood is generally denser than pine plywood.

Moisture Content: Plywood can absorb moisture, which increases its weight.

Construction: The way the plywood is constructed (the number of plies, the type of glue, etc.) can affect its weight.

Summarize

Recognizing the attributes of plywood that relate to size, thickness, core material, and geographical variables will serve as a guideline for selecting the right plywood for any specific project. In determining the best plywood for your particular project, it would be prudent to consider its intended usage; whether for structural or decorative purposes, budget constraints, environmental factors, and desired aesthetics. The better informed you are regarding nominal versus actual thickness, plywood tolerances, and core material types, the more likely that your plywood will be durable, cost-effective, and aesthetically pleasing. Proper planning and selection will ultimately increase the success of your project and save time and resources.

FAQ

Why is 3/4-inch plywood actually less than 3/4-inch thick?

This is because the thickness of plywood is usually marked as a nominal thickness, and the actual thickness is slightly thinner. During the manufacturing process, the surface of the plywood is sanded, which slightly reduces the final thickness. The actual thickness of 3/4-inch plywood is usually about 18 mm.

How to choose the right plywood for your project?

When choosing plywood, you need to consider the purpose of the project, budget, environmental factors, and aesthetic needs. If it is a structural project, it is recommended to choose a thicker plywood, such as 3/4-inch or 18-mm thickness, and choose a core material with good load-bearing capacity; if it is a decorative project, you may need to choose an MDF core plywood with a smooth surface.

How to avoid the problem of inappropriate plywood size?

Before purchasing plywood, make sure to measure the required dimensions accurately and consider the tolerances of the plywood. Especially in projects that require precise dimensions, it is best to confirm the actual thickness before purchase and test and adjust in advance during construction.